AyMINE – Technical documentation

Modules

Task, project & quality management

Task, project & quality management

Manager approval with the task report

Why some data can't be deleted

Adminitration of areas, projects, calendars

Region / project / methodology

Change management process in a project

GDPR and record of qualifications

Qualification of user or contact

Right to Manage Qualifications

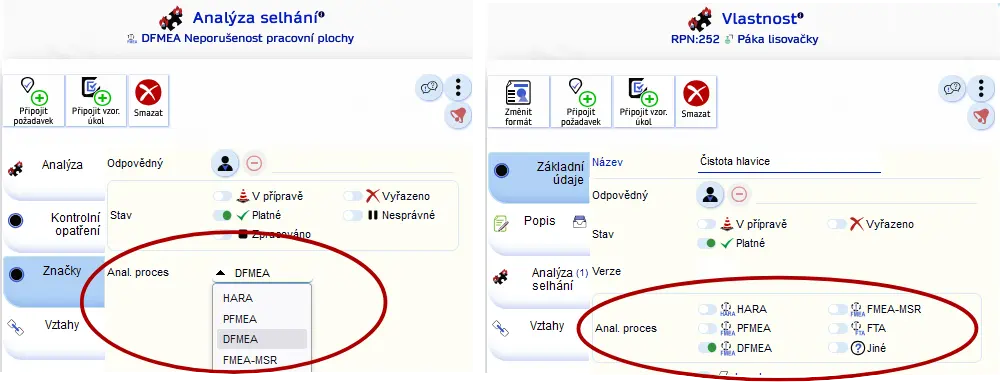

Failure Analysis for an Individual Property of a Component or Process

FMEA – Probability of Detection

FMEA – Probability of Occurrence

Task, project & quality management

Task, project & quality management

Administration of the Task Management Module

System rights for the task management module

Improvements and Preventive Measures

Methodology and Quality Management systems

What a methodology / QMS consists of

Problems, tickets and their management

Collaborative Resolution of Multiple Problems

Customer Service Response Generation

Incident and Quality Issue Management

Objects affected by the problem

Problems, Incidents, Helpdesk Tickets

Return project plan by baseline

Sample tasks and methodologies of the area

Effect of the task on the right to modify the attached object

The person responsible for the task

Working procedure – task definition

Objects related to the task pattern

Contacts and directories module (CRM)

Contacts and directories module (CRM)

Order overview for customer groups

Contacts and directories module (CRM)

Contacts and directories module (CRM)

System Permissions and CRM Module Settings

Send bulk messages in compliance with GDPR

How to correctly forget a person's details

Unsubscribe and set preferences

for bulk mail

Web management and automation

Web management and automation

Receiving a message from the web

Human resources

Personalistics – User Permissions

Human Resources module security

Manage department / division data

Overview of Personnel Information for pracov# Employment Contract

Synchronizing staff and system users

Products, assets and sales

Products, assets and sales

Received order for goods or services

Finance management

Metrics and Measurements

Technical Modules

Sabre plugin module

Enterprise Architect connector

Database link to Enterprise Architect database

Enterprise Architect connector

System Modules

The AyMINE Framework Module

The AyMINE Framework Module

AyMINE — Tips for Mobile Usage

Configure how your system looks and works

Gestures and Keyboard Shortcuts

More about how the system works

Private notes and tags for objects

Overview of Modules and Record Types

Filtering in the list of records

System Management

System Management

Additional functions with files

Copying and moving files between objects

Files (documents) linked to the object

Formatted texts in the application

Gateway settings for external messages

IMP gateway settings for email communication

Internet Call Gateway Settings

Message with the outside world

FMEA – Probability of Detection

FMEA – Probability of Detection

Probability of detecting a failure if it has occurred.

The definition varies for different types of FMEA analysis. Therefore, it is necessary to specify the type of analytical process (for individual failures or for properties).

The following overview is based on the automotive industry standard. Before using, check whether it is relevant for your case!

DFMEA

Level 1: It is known that the design cannot fail

Level 2: Verified standard procedures, aging control

Level 3: Verified standard procedures, failure test

Level 4: Verified standard procedures, function pass test

Level 5: Verified standard procedures in the late development phase, aging control

Level 6: Verified standard procedures in the late development phase, failure test

Level 7: Verified standard procedures in the late development phase, low, function pass test

Level 8: New test procedures are used, which are not verified

Level 9: Known tests are not specifically designed to verify potential failures

Level 10: Test procedures have not yet been developed

PFMEA

Level 1: Failure is virtually impossible or cannot go undetected

Level 2: Proven reliable detection methods; machine inspections prevent the occurrence of defective products

Level 3: Proven detection methods; defective products are automatically detected

Level 4: Proven detection methods; reliable inspections detect the problem during production and reject defective products

Level 5: Verified inspections; semi-automatic detection alerts the operator

Level 6: Verified inspections; manual inspection of products or samples detects defects

Level 7: Unverified inspections; semi-automatic detection alerts the operator

Level 8: Unverified inspections depend on manual inspection of products or samples to detect defects

Level 9: It is unlikely that inspections will detect the problem; sample checks may not easily identify the issue

Level 10: It is unlikely or impossible to detect the issue through inspections

FMEA-MSR

Level 1: Always detected – significantly more than 99.9%; the system responds to failures

Level 2: Detected with probability > 99.9%, the system is very likely to identify the failure

Level 3: Automatic detection identifies failures with probability > 99% with a short response time, automatic reaction is highly probable

Level 4: Detection with probability > 97% with medium response variability; the system will usually react to failures

Level 5: Detection with probability 90–97%, with moderate response variability; the system will usually respond automatically to failures

Level 6: The failure is detected by the user or system with probability > 90% and will likely be able to respond

Level 7: Low probability that the us