AyMINE – Technical documentation

Modules

Task, project & quality management

Task, project & quality management

Manager approval with the task report

Why some data can't be deleted

Adminitration of areas, projects, calendars

Region / project / methodology

Change management process in a project

GDPR and record of qualifications

Qualification of user or contact

Right to Manage Qualifications

Failure Analysis for an Individual Property of a Component or Process

FMEA – Probability of Detection

FMEA – Probability of Occurrence

Task, project & quality management

Task, project & quality management

Administration of the Task Management Module

System rights for the task management module

Improvements and Preventive Measures

Methodology and Quality Management systems

What a methodology / QMS consists of

Problems, tickets and their management

Collaborative Resolution of Multiple Problems

Customer Service Response Generation

Incident and Quality Issue Management

Objects affected by the problem

Problems, Incidents, Helpdesk Tickets

Return project plan by baseline

Sample tasks and methodologies of the area

Effect of the task on the right to modify the attached object

The person responsible for the task

Working procedure – task definition

Objects related to the task pattern

Contacts and directories module (CRM)

Contacts and directories module (CRM)

Order overview for customer groups

Contacts and directories module (CRM)

Contacts and directories module (CRM)

System Permissions and CRM Module Settings

Send bulk messages in compliance with GDPR

How to correctly forget a person's details

Unsubscribe and set preferences

for bulk mail

Web management and automation

Web management and automation

Receiving a message from the web

Human resources

Personalistics – User Permissions

Human Resources module security

Manage department / division data

Overview of Personnel Information for pracov# Employment Contract

Synchronizing staff and system users

Products, assets and sales

Products, assets and sales

Received order for goods or services

Finance management

Metrics and Measurements

Technical Modules

Sabre plugin module

Enterprise Architect connector

Database link to Enterprise Architect database

Enterprise Architect connector

System Modules

The AyMINE Framework Module

The AyMINE Framework Module

AyMINE — Tips for Mobile Usage

Configure how your system looks and works

Gestures and Keyboard Shortcuts

More about how the system works

Private notes and tags for objects

Overview of Modules and Record Types

Filtering in the list of records

System Management

System Management

Additional functions with files

Copying and moving files between objects

Files (documents) linked to the object

Formatted texts in the application

Gateway settings for external messages

IMP gateway settings for email communication

Internet Call Gateway Settings

Message with the outside world

FMEA Analysis Process

FMEA Analysis Process

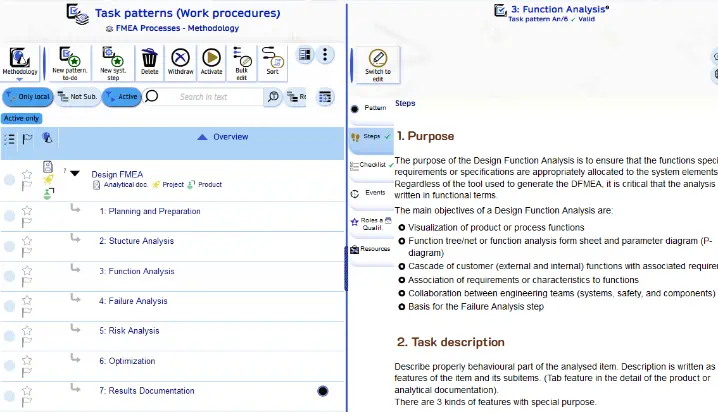

The FMEA analysis process consists of 7 steps

FMEA Methodology in AyMINE

AyMINE has a predefined methodology for the FMEA process (of course, you can modify it or create your own methodology).

You only need to generate a set of tasks based on templates in the methodology.

Overview of FMEA Steps

These sections do not describe the entire process but rather its implementation within AyMINE. For a complete understanding of FMEA, we recommend our training, and details are also described within the FMEA process itself. The goal of this page is to provide a global perspective on the process, which may not always be evident from individual tasks.

Step 1 - Planning and Preparation

FMEA preparation is guided by a standard FMEA process. The process can be initiated by the project manager or the product owner. It should be linked to the analyzed product or process. Its connection can be made both to a product already recorded in the product database and to analysis elements, such as a manufacturing process.

A key part of step 1 is defining the team that will conduct the FMEA analysis. The leader nominates team members for the analysis task, but not for the preparation task, which remains their responsibility.

The planning of further steps depends on the availability and size of the team:

- Responsibility for reviewing and possibly supplementing the analysis of the examined subject. The responsible worker receives the FMEA - step 2 task.

- Responsibility for preparing the functional analysis - FMEA - step 3.

- Inviting experts to a meeting for failure and risk analysis. It is necessary that they familiarize themselves with the analysis beforehand, so there should be enough time between completing steps 2 and 3 and starting step 4 (the time depends on whether independent experts unfamiliar with the subject are involved).

Another important part is planning the analytical meetings where steps 4 and 6 will be carried out.

A high-quality plan and preparation may seem partly obvious and partly unnecessary. However, thorough preparation determines whether the analysis will be effective.

- Clearly define the scope of the analysis, i.e., the exact boundaries of the analyzed subject (process, product).

- Assess who truly understands the topic and assemble a competent team.

- Plan the preparation, including the preparation of background materials and all other steps.

Step 2 - Structural Analysis

The output is the structure of the subject, either in the form of components (for a product) or process steps and used equipment (for a process).

If product analysis is used for structural analysis, the outputs can be visualized using Enterprise Architect. (This requires a connection via the eacon connector to the EA model.)

By using a documented component base, it is possible to build on an already existing previous FMEA analysis. Therefore, it is advisable to use already entered components whenever possible and not create duplicates in the structural analysis.

Step 3 - Functional Analysis

The output consists of descriptions of properties, operating modes, and states in detail for individual units. At the component level, the relevant properties for FMEA should be described. These descriptions are directly linked to the elements, so functional analysis can logically only be performed after structural analysis.

The primary tool for verifying functional analysis is fulfilling the functional specification of the product or process using properties (a general term including):

- General property

- Functionality

- Operating mode

If a repeated FMEA analysis of a component is conducted for another purpose, documentation from the previous analysis can be used, or a new analysis can be created for the same element. Therefore, it is possible to specify for each property which analysis it is included in. (If not specified, it is included in all.)

Step 4 - Failure Analysis

Possible failures are entered for each property. Failures can be recorded in bulk for each property, but it is better to list them individually as failure cases (tab in the detail view).

Possible failure cases become documentation for the property or component (or process step). These cases are further analyzed in step 5.

Each component and each property are recorded separately, so splitting FMEA analysis into multiple groups is not an issue if it makes sense based on different properties.

Note on permissions: The analysis can be conducted by those who are active collaborators in the area or project where the analysis is performed. At the same time, they must have permission to access the analyses. This allows for proper control over who participates in the analysis.

Documentation quality: We recommend that all those participating in the analysis be listed as team members for this task. The team composition is part of the analysis documentation, based on the list of participants. For meetings, organize discussions, where FMEA will be the only agenda item. This ensures that the meeting will focus solely on FMEA.

Step 5 - Risk Analysis

Risk analysis builds on failure analysis – it adds data to failure cases recorded in step 5 of the FMEA process. Essentially, new rows should not be added to the FMEA – they correspond to possible failures, and only those already identified will be examined.

Step 6 - Optimization

Like step 5, step 6 is based on the preparation from steps 2 and 3. For each failure and risk analysis, the system calculates the action priority for risk minimization. (The system also calculates the older RPN, as many teams are still accustomed to using this index.)

A critical part of optimization is designing changes that reduce the likelihood of failure. Each failure can be differentiated between current minimization tools and newly proposed measures.

New measures are documented in the analysis, and expected values are recorded – the analysis output is thus not only the current state but also the state after implementing all measures.

Tasks and Requirements for Resolution

Measures from the analysis are further reflected in change requests or tasks to address the problem. Both can be created directly in the failure case detail or the property detail. The request or task is created with a link to the potential failure, making it clear why the request or task was created and allowing tracking of whether it has been resolved.