AyMINE – Technical documentation

Modules

Task, project & quality management

Task, project & quality management

Manager approval with the task report

Why some data can't be deleted

Adminitration of areas, projects, calendars

Region / project / methodology

Change management process in a project

GDPR and record of qualifications

Qualification of user or contact

Right to Manage Qualifications

Failure Analysis for an Individual Property of a Component or Process

FMEA – Probability of Detection

FMEA – Probability of Occurrence

Task, project & quality management

Task, project & quality management

Administration of the Task Management Module

System rights for the task management module

Improvements and Preventive Measures

Methodology and Quality Management systems

What a methodology / QMS consists of

Problems, tickets and their management

Collaborative Resolution of Multiple Problems

Customer Service Response Generation

Incident and Quality Issue Management

Objects affected by the problem

Problems, Incidents, Helpdesk Tickets

Return project plan by baseline

Sample tasks and methodologies of the area

Effect of the task on the right to modify the attached object

The person responsible for the task

Working procedure – task definition

Objects related to the task pattern

Contacts and directories module (CRM)

Contacts and directories module (CRM)

Order overview for customer groups

Contacts and directories module (CRM)

Contacts and directories module (CRM)

System Permissions and CRM Module Settings

Send bulk messages in compliance with GDPR

How to correctly forget a person's details

Unsubscribe and set preferences

for bulk mail

Web management and automation

Web management and automation

Receiving a message from the web

Human resources

Personalistics – User Permissions

Human Resources module security

Manage department / division data

Overview of Personnel Information for pracov# Employment Contract

Synchronizing staff and system users

Products, assets and sales

Products, assets and sales

Received order for goods or services

Finance management

Metrics and Measurements

Technical Modules

Sabre plugin module

Enterprise Architect connector

Database link to Enterprise Architect database

Enterprise Architect connector

System Modules

The AyMINE Framework Module

The AyMINE Framework Module

AyMINE — Tips for Mobile Usage

Configure how your system looks and works

Gestures and Keyboard Shortcuts

More about how the system works

Private notes and tags for objects

Overview of Modules and Record Types

Filtering in the list of records

System Management

System Management

Additional functions with files

Copying and moving files between objects

Files (documents) linked to the object

Formatted texts in the application

Gateway settings for external messages

IMP gateway settings for email communication

Internet Call Gateway Settings

Message with the outside world

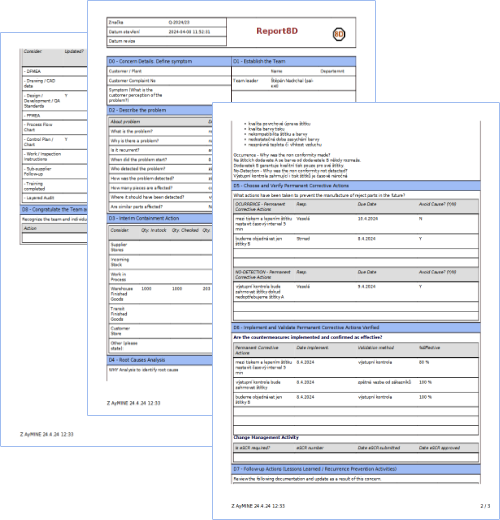

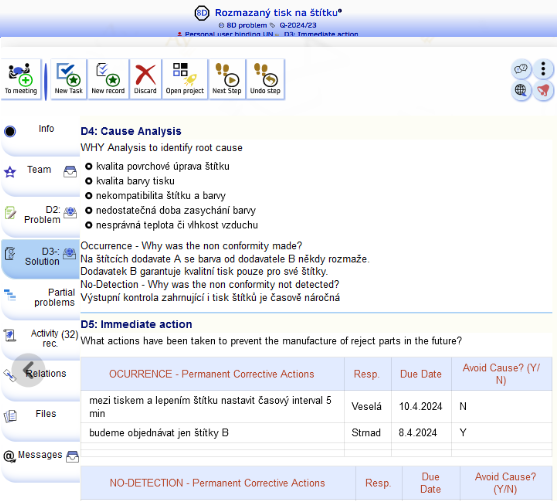

8D report – system support

8D report – system support

AyMINE supports detailed 8D report development as well as their mandatory registration

- How to base an 8D

- How the 8D report works

- 3D – Determine immediate actions

- 4D – Analysis of causes

- How to make a new template for 8D

- Don't you see 8D in the system?

An 8D report can be created for any product, a specific production tool, or even without a direct link to the product.

Therefore, you typically base an 8D report:

- Within the production control area without a direct link to the tool

- Directly at the tool

- At the manufactured product

- At the specific product – typically if it is

- It is a piece product,

- A defective product caught at the output control

- As part of the pre-production testing.

How to base an 8D

You base an 8D report as another problem – with the button new problem in the detail of the asset, product, or on the worktable area in which you manage the production. Change the problem to an 8D report on the top bar with the button Change to 8D .

When switching to 8D, you can select a template for the 8D report to be pre-filled with. With respect to the 8D customer you require, we may have templates prepared in different languages or structures within methodology as required by the customer (e.g. a template for a VW group).

By changing a common problem to 8D, you can easily reassign to formal processing any problem you find in the course of the solution that it requires the systematic approach that the 8D report leads to.

How the 8D report works

8D support accompanies you through the steps until it is closed – the 8D state.

1D – Identifying the problem and setting up a team

In the first step, name the problem and attach it to the records it relates to – typically the product (or even the specific product, or the production facility affected by the problem). Always link 8D to the product if it relates to its production – this is important for a possible audit from the customer

Set up the team that 8D solves

The team is set up on the team tab page. Everyone who is on the team of the 8D report is there for a specific competence. The template can define specific competencies that must be filled in the team – these are created in the 8D report, but need to be filled. The system allows you to only fill the position in the team with staff who actually have the necessary qualifications

When finished, go to the next step with the Advance button.

2D – Problem description

On the D2 tab: Problem describe all details that are important for the problem analysis. You can add images (it is recommended to insert images separately in the attachments on the Files tab) or even documents (e.g. photos or other customer documents).

3D – Determine immediate actions

As part of the step, suggest how to prevent the problem from threatening the production or quality of the products as soon as possible. The description of the actions must be given in the 3D report description and evaluated whether they were effective.

Processing note 8D: The report allows you to go to the next step even if the previous one is not completed, but it also documents whether you are going back. If you do not evaluate the effectiveness of the action immediately, you can return to the 3D step later. However, the information where you processed which particular step last will be saved.

You can return to the previous step by clicking Revert Step.

4D – Analysis of causes

The key step of the analysis is to find out why the problem occurred and that is what step 4D is for. The results of the analysis are recorded in a separate field – the standard template presents the basic questions, which are instructive but not binding. In no case can the analysis be reduced to the usual questions if they do not lead to finding the causes.

Recommendation: Use the FMEA Product Analysis or the production process to get into the detail of the problem.

How to make a new template for 8D

Part of our automotive methodology is the default template in English, which is based on the commonly used template. The easiest way to make your own template is to create a copy of the existing one in the methodology and edit it.

Caution: To be able to edit templates in the methodology, you need to be a member of the quality department and have the rights to do so

Don't you see 8D in the system?

The ability to use 8D report is part of the quality management package. It is therefore imperative that you have this package active.

8D report can only be started by workers who are actively involved in the quality management process. It is therefore imperative that they have this process active – it is set up in the system administration (see User Process Management. ) Anyone who works in the area where it was started can participate in the processing of the 8D report. Therefore, not everyone may have the rights to manage the quality process, but really only those workers who make the decision to set up the 8D report.